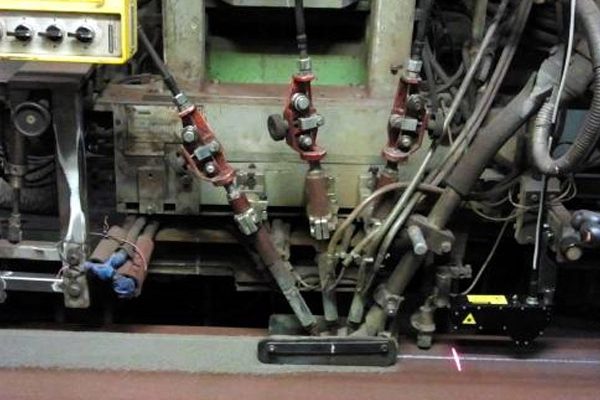

Designation. A system is designed for automatic tracking of a joint center with groove without filling or with partial filling after technological pass in arc welding or submerged-arc welding. The system consists of two main elements, namely laser sensor (LS) equipped with microprocessor controller and communication module (CM).

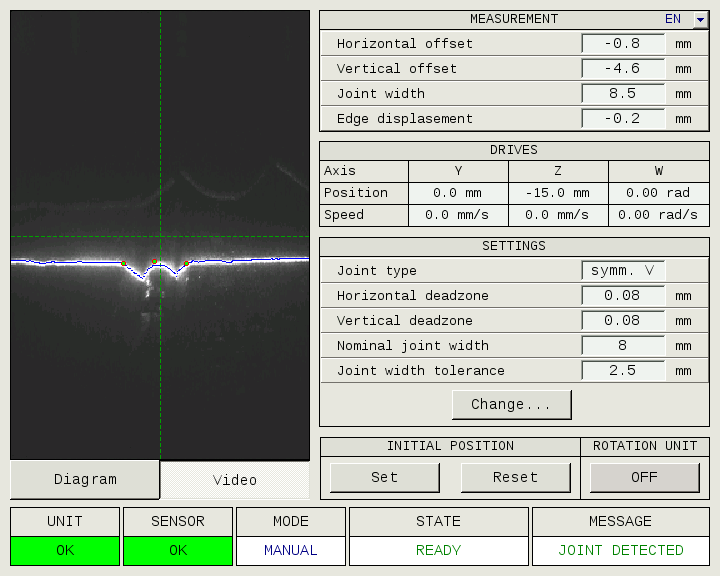

The laser sensor is designed for contact-free measurement of transverse and longitudinal displacement of the joint center and communication of the measurement results to the communication module via RS-422 interface. The laser sensor is also equipped with TV output for visual tracking of system work. The main functions of the communication module are data receiving from the laser sensor, formation of the signals of vertical and transverse correction of welding head position, rapid adjustment of the tracking system, interaction with the main controller of the welding mill, operator panel and external computer for service parameterization and tracking system setting.

The tracking system is imbedded in existing process equipment of the welding mill. The sensor TV output is connected to available display of the remote video monitoring. The communication module is equipped with necessary interfaces, digital and/or analogue inputs/outputs for interaction with the main controller of the welding mill and operator panel (list of necessary signals is additionally agreed with the Customer depending on welding mill type).

The tracking system is designed based on modern electron components and printed-circuit board of commercial designation that provides increased reliability of the delivered equipment.

Main advantages of tracking system

- high sensitivity to groove depth due to large triangulation angle provides reliable joint tracking in thin-wall pipe welding;

- no Windows operating system;

- time of system loading after switching makes 3-4 seconds;

- no computer in tracking system structure;

- transformer galvanic isolation of power supply and signal circuits is installed directly in the sensor block that allows eliminating effect of electromagnetic fields of welding cables;

- replaceable sensor blocks and communication modules cut expenses for spare parts;

- simple maintainable cables;

- TV output that allows visual monitoring of tracking process for welder;

- available information on real groove width and exceeding of edges in real time;

- unique optical path allows eliminating effect of flecks and outside flashes on joint tacking process;

- protection glasses of standard 20 and 30 mm diameters can be easily replaced for several minutes.

Performance characteristics

| Accuracy of joint center tracking in transverse and vertical directions, mm | ±5 |

| Operating area of laser sensor in transverse direction, mm | ±30 |

| Operating area of laser sensor in vertical direction, mm | ±25 |

| Nominal distance from sensor to pipe, mm | 80 |

| Minimum allowable residual groove depth, mm | 3 |

| Maximum length of communication line between laser sensor and communication module, m | 50 |

| Standard of output TV signal of sensor | PAL |

| Power supply | +24 В |

| Consumed power, W, not more | 20 |

| Breakdown voltage of sensor galvanic insulation, kW, not less | 1.6 |

| Sensor IP protection | IP64 |

| Operating temperature range, °С | -10..+65 |